ApplicationsOffest ink

Automation of a filling process performed manually by experienced workers

Fluid name: Offset ink

/ Industry type: Chemical

Current Problem/Request

Current Problem/Request

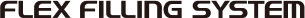

The ink emitted from the roll mill is received by the pump hopper, and a can on the scales is filled manually with a three-directional valve on the circular route, but this presented the following issues.

- With the relatively inexperienced workers filling speed drops drastically, so specialized, experienced workers are needed.

- The valve's fluid control is bad and contaminates the rim of cans.

- Under the current method, the pump is very noisy and disruptive to the work environment.

Solution

Solution

In order to automate the chain of operations, we made the following suggestion.

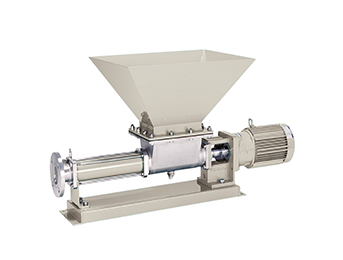

- Replace the previous pump with a hopper-type NYS pump that can perform metered supply of even high-viscosity ink and doesn't make noise apart from the sound of the motor.

- Set up a JAST Valve (filling valve) at the end of the pipe. We installed a load-cell type scales with a roller conveyor underneath the valve, and used a controller that automated the whole process from calculating the net weight of the ink to filling it, by placing an empty can on top of the scales.

Benefits

- It is a weight-filling system interlocked with the load-cell type scales, so regardless of the worker's experience level, filling with a high degree of precision is now possible.

- The JAST Valve's good fluid control prevented contamination of containers, making the unnecessary tasks such as wiping off a thing of the past.

- By eliminating noise, the work environment was improved.

Flowchart

Related products

Product information

Metered filling machine that combines the outstanding performance of Mohno Pumps with fluid-controlling JAST Valves and controllers.

Product information

General-purpose Series

General-purpose Series

Standard model capable of non-pulsating, metered conveyance.

- Food

- Chemical

- Cosmetic

- Electrical machinery