ApplicationsFace cleansing cream

Cutting down on heavy labor by automatically

feeding face cleansing cream into the filling device

Fluid name: Face cleansing cream

/ Industry type: Cosmetic

Current Problem/Request

Current Problem/Request

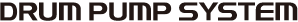

We have the process of supplying face cleansing cream in a tank to a filling device hopper. Because of the high viscosity, it is not possible to perform the suction work with the current pump, so we do the work of supplying it to the hopper by hand. But this presented the following problems.

- If the cream is spilt, it not only contaminates the work environment, but is slippery and dangerous.

- Lifting up the high-viscosity cream and carrying it high up to the hopper is pretty hard work.

- We also need to monitor the filling device hopper constantly so it doesn't empty, which is a drain on manpower.

- The tank and hopper are exposed to the outside air, so there is a danger of contamination by foreign substances.

Solution

Solution

Use a Drum Pump System that can perform suction on even high-viscosity fluids. By attaching a sensor to the filling device hopper to detect remaining fluid, the pump's automatic start-stop could be controlled, which enabled us to automate both the suction from the tank and the supply to the hopper.

Benefits

- Because of the clean pipe conveyance, the work environment not only became cleaner, but hard and dangerous labor became a thing of the past. We also eliminated the need to monitor the leftover fluid, allowing workers to focus on other important tasks.

- Because the Drum Pump System seals the tank and draws the fluid, we were able to drastically cut down on the risk of foreign matter contamination.

Flowchart

Related products

Product information

Extracts high-viscosity fluid directly from various containers, contributing to the automation and streamlining of processes.

- Food

- Chemical

- Cosmetic

- Electrical machinery