ApplicationsOffset ink

Automation of the process of supplying high-viscosity ink to a roll mill,

reducing heavy labor

Fluid name: Offset ink

/ Industry type: Chemical

Current Problem/Request

Current Problem/Request

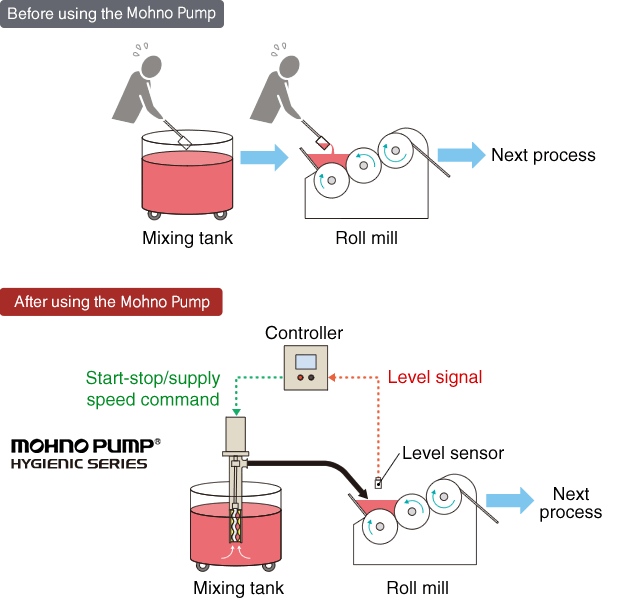

During large-scale trituration and dispersal of ink, high-viscosity ink is drawn out with a ladle, and fed into the roll mill. This process is performed manually, but the following issues presented themselves.

- It is hard work that needs to be performed repetitively and menially, and workers develop tendonitis.

- The work of feeding into the roll mill takes a long time, and takes time away from the mixing work.

Solution

Solution

By using NTH, which can perform metered suction and conveyance from the mixing tank even of high-viscosity offset ink, we were able to perform suction directly from the mixing tank and automate supply to the roll mill. Additionally, a level sensor is equipped on top of the roll mill for fluid surface detection. We used a controller that can switch the pump drive on or off once the fluid surface reaches its minimum or maximum level, respectively, and can perform automatic supply of ink such that the fluid surface level is within the set parameters.

Benefits

- Because we were able to automate the roll mill supply process, avoiding heavy labor so that the mixing procedure can be performed by one person alone.

- Because it can run in reverse, the ink left in the discharge pipe can be removed at the end, minimizing material waste.

Flowchart

Related products

Product information

Standard sanitary pump model that supports a wide range of fluids from watery fluids to high-viscosity fluids.

- Food

- Chemical

- Cosmetic

- Electrical machinery